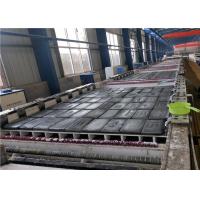

We provide hot dipped galvanized wire production line which is

producing hot dipped galvanized

steel wire,it is widely used in making wire mesh fence products and

construction field.

Hot dip galvanizing machine production line characteristics

Wire take up machine: adopts inverted plum blossom take-up unit,

which adopts variable frequency

speed-regulating motor, and the take-up speed is adjustable. Each

take-up reel is equipped with a

4.0KW and a 0.75KW motor. When the wire is taken up, the wire is

flat. The wiring is stable and

the disc weight is 800-1000kg, which is convenient for workers to

operate.

Hot dip galvanizing machine production line technology

| Low carbon steel wire | According to the standard of hot-dip galvanizing and zinc-aluminum

alloy for low carbon steel wire |

| Product specification | 1.6-4.0mm |

| Tensile strength | low carbon 450 N/mm2 ~ 550 N/mm |

| Zinc layer thickness | galvanized 40~80/150~ 300 g/m2 zinc aluminum 150~ 300 g/m2 |

| Production speed | D / V40 to 60, maximum 80 |

| Number of steel wire | 24 |

| Steel wire spacing | pre-treatment 35mm; zinc 45mm |

| Heating energy | mixed gas or converter gas, electric energy |

Hot dip galvanizing machine production line theory

1) the steel structure of the furnace body adopts the overall frame

dimensions: L26000*W2400*H1800(mm)

2) the net width of the furnace: 1250 (mm), the distance of the

steel wire in the furnace; 35 mm;

3) fuel type: mixed gas or converter gas (heat value: ≥ 1250 KCal)

4) contact pressure: normal 0.012MPa, fluctuation ≤ 5% pressure

value.

5) contact pipe diameter: DN80

6) using a four-stage assembly of countercurrent furnace type,

direct-fired type and premixed burners are

used together to control the atmosphere and pressure in the furnace

Hot dip galvanizing machine production line advantage and selling points

1. The heat treatment furnace adopts a countercurrent open flame

heating type furnace. The furnace body is

a three-stage combination. The preheating section, the heating

section, the heating section and the heating

section are respectively set up from the inlet. The heating of each

section is relatively independent and affects

each other. According to the requirements of the heat treatment

process, the furnace temperature and

atmosphere can be set in stages to meet the processing

requirements.

2. The heat treatment furnace steel wire inlet and outlet furnace

door is designed with mechanical transmission

device, and the furnace door is opened to facilitate the structure

to reduce the cold air intake and fire.

3. The heat treatment furnace adopts an energy-efficient waste heat

recovery device. The high-temperature

gas discharged from the furnace is recovered by the heat exchanger,

and the combustion air is used for the

burner to improve the thermal efficiency of the furnace to save

energy. Generally, the combustion air per

combustion Increasing 100 °C saves 5% of fuel.

4. heat treatment furnace temperature control

(a) The control system has two control modes, manual and automatic.

The main control PLC adopts

the Siemens S300 series products to ensure accurate and stable

control.

(b) The temperature and air-fuel ratio of each section can be

adjusted according to the process requirements.

(c) Features of the equipment: The open flame annealing furnace

adopts multiple burner heating methods on

both sides, the heating temperature is uniform, the surface of the

steel wire is not easily damaged, the pass

rate is high, the temperature control accuracy in the furnace is

high, below 1000 °C, according to steel

The actual condition of the wire regulates the temperature and is

stable and reliable. The two-stage heating

zone is completely made according to the heat treatment curve of

the steel wire to ensure complete phase

transformation of the steel wire in the furnace, the temperature

transition is stable, the pass rate of the pass

bar can reach more than 99%, the oxidation burn rate is 0.145%, and

the lateral temperature difference

in the furnace is ±2. °C.

Hot dip galvanizing machine production line FAQ

Q: Can you make a proposal for me

A: Yes, our technician will make a reasonable proposal for you

Q: What information should i give to you to make proposal?

A:

1. Material: low carbon or high carbon

2. Capacity: tons per month

3. Wire diameter: mm

4. Zinc coat thickness: g per square meters

5. Wire usage: for which application

6. Energy: natural gas, LPG, electricity

7. Workshop size: L*W

Q: How is the delivery time

A: 3 months after receiving down payment

Q: How is the payment:

A: L/C T/T

30%T/T as deposit

70% balance payment when delivery via L/C at sight or T/T

Q: We also need drawing machine,can you supply that

A: Yes, drawing machine is the first step of the galvanized wire

production line, we are also manufacturing it

Q: How about after sales service

A: Quality guarantee for one year, technical support for whole

equipment lifetime

Hot dip galvanizing machine production line after sales service

1. Test the machine before shipment

2. Guarantee time: one year since machine was at buyer's factory

but within 18 months against B/L date

3. Within guarantee time, if any components are broken under normal

condition, we can change for free

4. We can send our best technician to buyer’s factory for

installation, debugging and training

5. Buyer need to undertake double-way air tickets, Visa, Worker

salary USD100.0/ Day, Accommodations

Company Introduction

Hebei OLT wire mesh machine company with 55 employees, 9000 square

meters workshop,

more than 30 years experience in metal wire mesh fence. All these

help us to be the leading manufacturer

in Metal wire Mesh and wire mesh machinery field, we are mainly

supplying wire drawing machine,

galvanized wire production line, chain link fence machine, wire

mesh welding machine,

razor barbed wire making machines, etc.

We can supply 100% right and reasonable suggestions for our new

customers.

Welcome to visit our factory to enable our mutual cooperation.